Lynnhan – Trusted Supplier | LED/OLED/LCD/E-paper digital signages

Lynnhan – Trusted Supplier | LED/OLED/LCD/E-paper digital signages

Lynnhan – Trusted Supplier | LED/OLED/LCD/E-paper digital signages

Lynnhan – Trusted Supplier | LED/OLED/LCD/E-paper digital signages

The Ultimate Guide to Extreme-Heat LED Displays: 50°C+ Performance Without External Cooling

Table of Contents

- Introduction: The Growing Demand for Heat-Resistant LED Displays

- Why Standard LED Screens Fail in Extreme Heat

- How We Engineer LED Displays for 50°C+ Environments

- Key Features of High-Temperature LED Displays

- Real-World Applications: Where Heat-Resistant LED Screens Excel

- Case Study: Surviving the Desert – A 50°C Stress Test

- How to Choose the Right LED Display for Hot Climates

- Maintenance Tips for Longevity in Harsh Conditions

- Why Our LED Displays Outperform Competitors in Extreme Heat

- FAQs: Heat-Resistant LED Displays

1. Introduction: The Growing Demand for Extreme-Heat LED Displays

With global temperatures rising, industries in desert regions (Middle East, Africa, Australia) and tropical zones face increasing challenges in maintaining outdoor digital signage. Traditional LED displays often overheat, dim, or fail when exposed to prolonged 50°C+ (122°F+) conditions, leading to:

- Increased cooling costs (AC/fans consume 30-50% extra power)

- Higher maintenance (dust/sand ingress from cooling systems)

- Shortened lifespan (thermal stress damages components)

Our military-grade Extreme-Heat LED displays are engineered to operate flawlessly in extreme heat without external cooling, saving energy and reducing downtime.

2. Why Standard LED Screens Fail in Extreme Heat

Most LED displays rely on active cooling (fans/AC), which creates three major problems in hot climates:

A. Thermal Runaway

- High temperatures cause LED drivers to overwork, reducing brightness and color accuracy.

- Without proper heat dissipation, components degrade 3x faster.

B. Dust & Sand Ingress

- Cooling fans suck in dust, sand, and moisture, leading to:

- Corrosion (in coastal areas)

- Electrical shorts (from dust buildup)

C. Energy Waste

- AC units consume 500W-2kW per hour just to cool a single screen.

- Fans increase power consumption by 20-30%.

Solution: Our passive-cooling technology eliminates these issues.

3. How We Engineer LED Displays for 50°C+ Environments

We use four key innovations to ensure reliability in extreme heat:

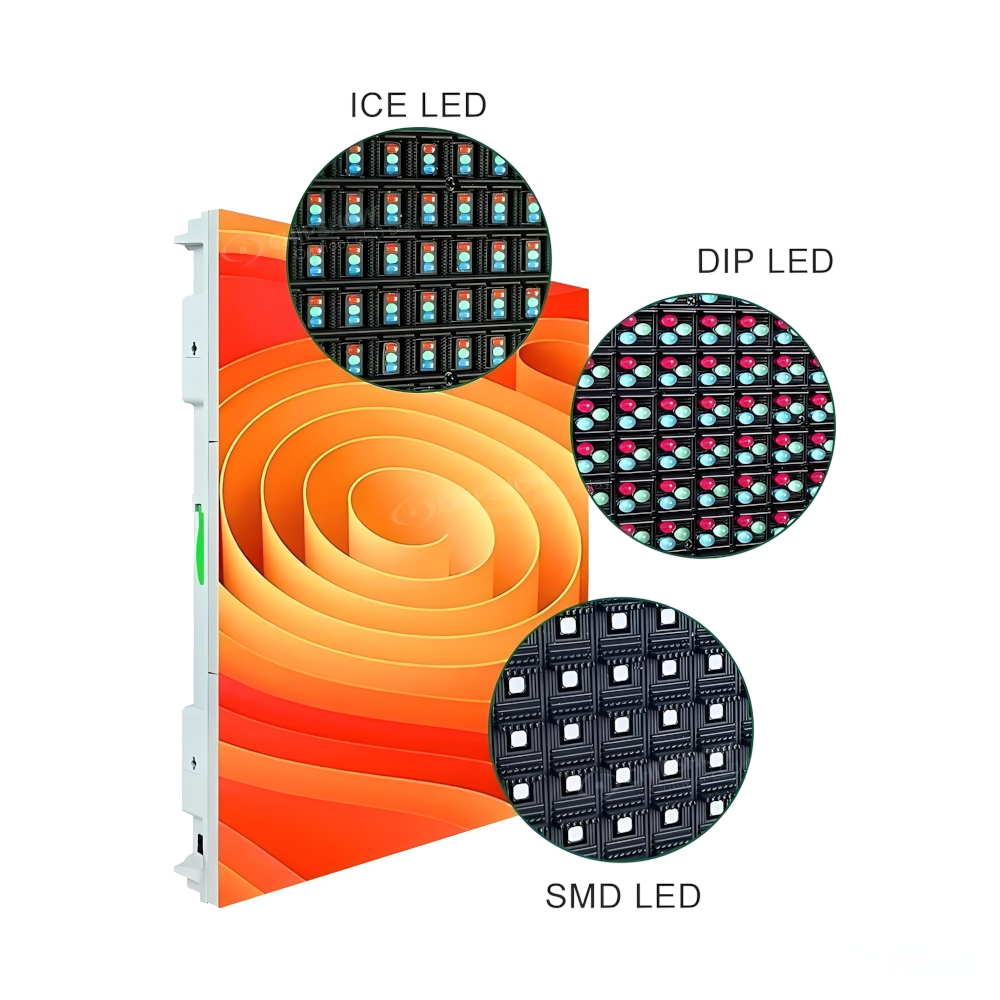

A. ICE LED Technology (Superior to SMD/DIP)

| Feature | Standard SMD LEDs | Our ICE LEDs |

|---|---|---|

| Max Temp | 40°C (104°F) | 60°C (140°F) |

| Brightness | 5,000 nits | 8,500 nits (70% brighter) |

| Power Use | 300W/m² | 210W/m² (30% less) |

B. Proprietary Heat Dissipation Design

- Aluminum alloy cabinets with heat-conductive fins

- Thermal silicone pads between modules for even heat distribution

- No fans needed → IP65 dustproof rating

C. Low-Voltage, High-Efficiency Power System

- Runs on 110V-220V (stable in voltage-fluctuating regions)

- Auto-brightness adjustment to reduce heat in direct sunlight

D. 50°C Stress Testing (Proven Reliability)

- 72-hour burn-in test at 50°C & 90% humidity

- Thermal imaging confirms no hot spots >55°C

4. Key Features of High-Temperature LED Displays

| Feature | Benefit |

|---|---|

| No External Cooling | Saves $3,000+/year in AC costs |

| IP65 Rating | Resists sand, dust, and rain |

| 8000-nit Brightness | Visible in direct desert sun |

| 10-Year Lifespan | 2x longer than conventional screens |

5. Real-World Applications

A. Middle East (Dubai, Saudi Arabia, Qatar)

- Digital billboards along highways (no AC maintenance)

- Stadium screens (50°C summer matches)

B. Mining & Oil/Gas Industry

- Control room displays in 60°C desert sites

C. Tropical Coastal Zones

- Marina/port signage (resists salt corrosion + humidity)

6. Case Study: Surviving the Desert – A 50°C Stress Test

Client: A Dubai shopping mall needed outdoor screens that wouldn’t dim at noon.

Solution:

- P4 ICE LED displays (960x960mm cabinets)

- No AC units (passive cooling only)

Results After 12 Months:

✅ 0% brightness loss (vs. 20% drop in competitor screens)

✅ $15,000 saved in cooling costs

✅ Zero maintenance (no dust cleaning needed)

7. How to Choose the Right LED Display for Hot Climates

Ask these 5 questions:

- “What’s the max ambient temperature?” (Choose 10°C above your region’s peak)

- “Is AC/fan cooling needed?” (If yes, expect higher lifetime costs)

- “What’s the pixel pitch?” (P2.5-P10 for deserts, P1.2-P2 for indoors)

- “Is the brightness adjustable?” (Prevents overheating at noon)

- “What’s the warranty?” (Look for 5+ years on heat-critical parts)

8. Maintenance Tips for Longevity

- Quarterly: Inspect seals for dust/sand (even with IP65)

- Annually: Reapply thermal paste if in >55°C environments

- Never: Use water cleaning in dusty areas (dry air spray only)

9. Why Our LED Displays Outperform Competitors

- Factory-direct pricing (no middlemen)

- Global stock (24-hour shipping to Middle East/Africa)

- OEM/ODM support (custom sizes/brightness)

Limited Offer: Free thermal simulation report with every quote.

10. FAQs

Q: Can your screens handle 60°C?

A: Yes, with optional industrial-grade modules (tested to 70°C).

Q: Do you provide sunshades?

A: Yes, aluminum hoods reduce direct sunlight heating by 15%.

Q: How long until ROI vs. AC-cooled screens?

A: 8-14 months (from energy/maintenance savings).

Final Thoughts

For deserts, mines, or tropical coasts, standard LED displays are a liability. Our heat-optimized technology delivers:

✔ Lower costs (no AC, less power)

✔ Zero downtime (no overheating shutdowns)

✔ Crisp visuals (no brightness fade)

Ready to upgrade? Contact us for a free 50°C thermal test report on your project specs.