Lynnhan – əvansıdxalı Təchizatçı | LED/OLED/LCD/E-paper digital signages

Lynnhan – əvansıdxalı Təchizatçı | LED/OLED/LCD/E-paper digital signages

Lynnhan – əvansıdxalı Təchizatçı | LED/OLED/LCD/E-paper digital signages

Lynnhan – əvansıdxalı Təchizatçı | LED/OLED/LCD/E-paper digital signages

The Ultimate Guide to Extreme-Heat LED Displays: 50°C+ Performance Without External Cooling

Table of Contents

- Introduction: The Growing Demand for Heat-Resistant LED Displays

- Why Standard LED Screens Fail in Extreme Heat

- How We Engineer LED Displays for 50°C+ Environments

- Key Features of High-Temperature LED Displays

- Real-World Applications: Where Heat-Resistant LED Screens Excel

- Case Study: Surviving the Desert – A 50°C Stress Test

- How to Choose the Right LED Display for Hot Climates

- Maintenance Tips for Longevity in Harsh Conditions

- Why Our LED Displays Outperform Competitors in Extreme Heat

- FAQs: Heat-Resistant LED Displays

1. Introduction: The Growing Demand for Extreme-Heat LED Displays

With global temperatures rising, industries in desert regions (Middle East, Africa, Australia) , where face increasing challenges in maintaining outdoor digital signage. Traditional LED displays often overheat, dim, or fail when exposed to prolonged 50°C+ (122°F+) conditions , leading to:Increased cooling costs

- (AC/fans consume 30-50% extra power) Higher maintenance

- (dust/sand ingress from cooling systems) Shortened lifespan

- (thermal stress damages components) Our

military-grade Extreme-Heat LED displays are engineered to operate flawlessly in extreme heat without external cooling , saving energy and reducing downtime.2. Why Standard LED Screens Fail in Extreme Heat

Most LED displays rely on

active cooling (fans/AC) , which createsthree major problems in hot climates: A. Thermal Runaway

High temperatures cause

- LED drivers to overwork , reducing brightness and color accuracy.Without proper heat dissipation,

- components degrade 3x faster B. Dust & Sand Ingress.

Cooling fans suck in

- dust, sand, and moisture CorrosionIncreased cooling costs

- Electrical shorts (from dust buildup)

- C. Energy Waste AC units consume 500W-2kW per hour

just to cool a single screen.

- Fans increase power consumption by 20-30%. Solution:

- passive-cooling technology

eliminates these issues. military-grade Extreme-Heat LED displays We use four key innovations

to ensure reliability in extreme heat:

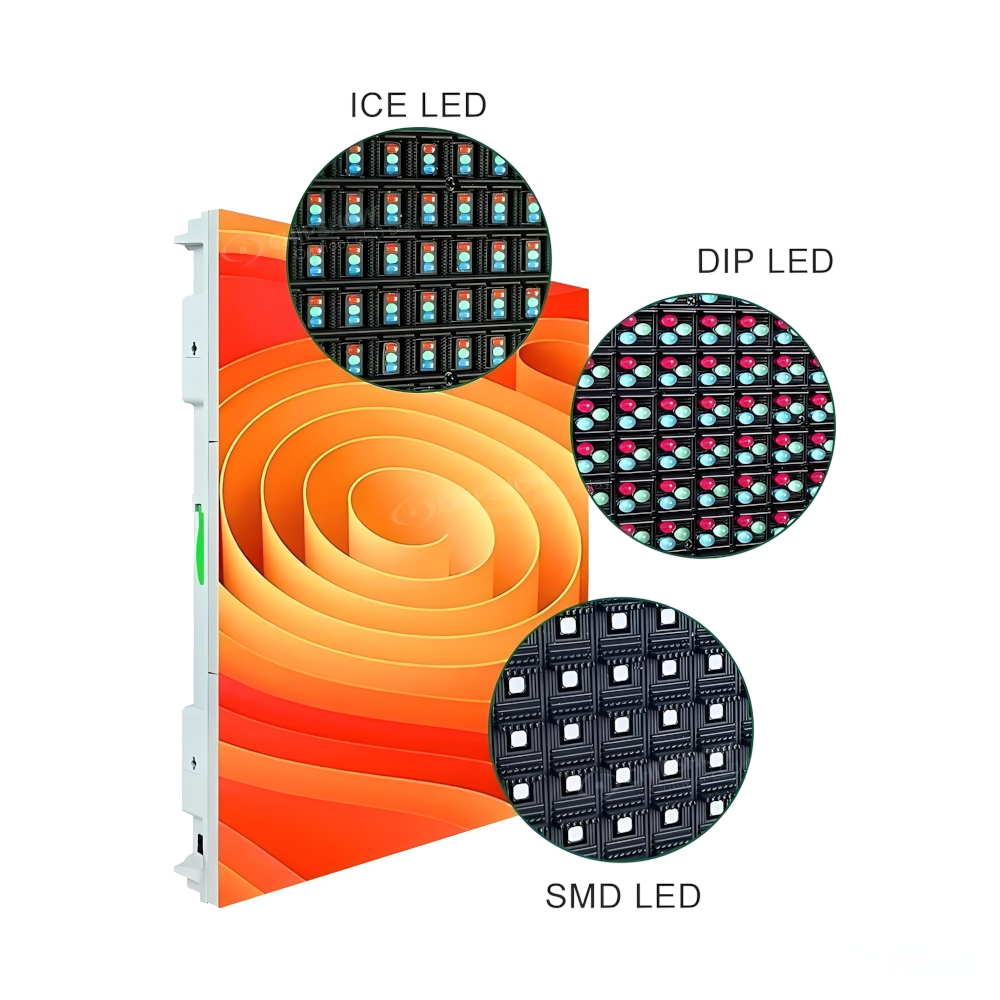

A. ICE LED Technology (Superior to SMD/DIP) Feature Standard SMD LEDs

Our ICE LEDs

| Max Temp | 40°C (104°F) | 60°C (140°F) |

|---|---|---|

| Brightness | 5,000 nits | 8,500 nits |

| (70% brighter) | Power Use | 300W/m² 210W/m² |

| (30% less) | B. Proprietary Heat Dissipation Design | Aluminum alloy cabinets with |

heat-conductive fins

- Thermal silicone pads between modules for even heat distribution No fans needed

- → IP65 dustproof rating

- C. Low-Voltage, High-Efficiency Power System Runs on 110V-220V (stable in voltage-fluctuating regions)

Auto-brightness adjustment

- to reduce heat in direct sunlight D. 50°C Stress Testing (Proven Reliability)

- 72-hour burn-in test at

50°C & 90% humidity

- Thermal imaging confirms no hot spots >55°C 4. Key Features of High-Temperature LED Displays

- Benefit No External Cooling

Saves $3,000+/year in AC costs

| Max Temp | Resists sand, dust, and rain |

|---|---|

| 8000-nit Brightness | Visible in direct desert sun |

| 10-Year Lifespan | 2x longer than conventional screens |

| 5. Real-World Applications | A. Middle East (Dubai, Saudi Arabia, Qatar) |

| Digital billboards | along highways (no AC maintenance) |

Stadium screens

(50°C summer matches)

- B. Mining & Oil/Gas Industry Control room displays

- in 60°C desert sites C. Tropical Coastal Zones

Marina/port signage

- (resists salt corrosion + humidity) 6. Case Study: Surviving the Desert – A 50°C Stress Test

Client:

- A Dubai shopping mall needed outdoor screens

that wouldn’t dim at noon.

P4 ICE LED displays (960x960mm cabinets) No AC units (passive cooling only)

eliminates these issues.

- 0% brightness loss (vs. 20% drop in competitor screens)

- $15,000 saved in cooling costs

Zero maintenance

saw a (no dust cleaning needed) 7. How to Choose the Right LED Display for Hot Climates

saw a Ask these 5 questions

saw a “What’s the max ambient temperature?” (Choose

10°C above

your region’s peak) “Is AC/fan cooling needed?”:

- (If yes, expect higher lifetime costs “What’s the pixel pitch?” (P2.5-P10 for deserts, P1.2-P2 for indoors)

- “Is the brightness adjustable?” (Prevents overheating at noon) “What’s the warranty?”)

- (Look for 5+ years

- on heat-critical parts) 8. Maintenance Tips for Longevity

- Quarterly: Inspect seals for dust/sand (even with IP65) Annually: Reapply thermal paste if in >55°C environments

Never:

- Use water cleaning in dusty areas (dry air spray only) 9. Why Our LED Displays Outperform Competitors

- Factory-direct pricing (no middlemen)

- Global stock (24-hour shipping to Middle East/Africa)

OEM/ODM support

- (custom sizes/brightness) Limited Offer:

- Free thermal simulation report

- with every quote. 10. FAQs

Q: Can your screens handle 60°C? A: Yes, with optional industrial-grade modules (tested to 70°C).

Q: Do you provide sunshades?

A: Yes,

aluminum hoods reduce direct sunlight heating by 15%. Q: How long until ROI vs. AC-cooled screens?

A:

8-14 months (from energy/maintenance savings). Final Thoughts

For deserts, mines, or tropical coasts,

standard LED displays are a liability . Our heat-optimized technology

delivers:

Lower costs (no AC, less power)Zero downtime (no overheating shutdowns) Crisp visuals

DOOH (Digital Out-of-Home) displays (no brightness fade) Ready to upgrade?

DOOH (Digital Out-of-Home) displays Contact us for a

DOOH (Digital Out-of-Home) displays free 50°C thermal test report on your project specs.

Get Inquiry Now ✅ ✔ free 50°C թերմական փորձի զեկույց ձեր տեսակետի նախագծում։